Table of Contents

Introduction

A malfunctioning compressor in your luxury Sub Zero refrigerator is more than an inconvenience–it’s an urgent issue that can put thousands of dollars’ worth of groceries and wine at risk. Today’s high-end kitchen appliances, especially sophisticated brands like Sub-Zero, demand expert solutions when problems arise. When timely and skilled repair is needed–particularly for compressor issues–choosing certified, specialized service is vital for preserving the performance, longevity, and value of your appliance.

Why Compressor Repair Matters

The compressor is the heart of your Sub Zero refrigerator. It maintains precise temperature control and energy efficiency–two essential features for keeping your perishables at their best. A malfunctioning compressor can quickly escalate into catastrophic cooling failure, risking food spoilage and even permanent damage to the sealed refrigeration system. The cost of neglect can be tremendous, both financially and in terms of appliance lifespan. That’s why timely Sub Zero refrigerator compressor repair by certified professionals is crucial.

Ignoring compressor issues doesn’t just risk your groceries–it can lead to expensive system-wide failures requiring complex sealed system repairs.

Signs Your Compressor Needs Repair

Early identification of compressor trouble can mean the difference between a fast, cost-effective fix and a major appliance failure. Common compressor failure signs include:

- Warm or uneven refrigerator temperatures

- Unusual or loud compressor noises

- Excessive cycling (the fridge turning on and off frequently)

- Frost or ice buildup inside the fridge

- Overheating at the rear of the unit

Addressing these symptoms promptly can prevent extensive damage.

The Cost and Value of Professional Repair

The reality is that compressor repairs on luxury appliances are complex and best left to professionals. While repair costs are higher than standard refrigerators, they’re justified by the complexity, specialized tools, and genuine Sub-Zero parts involved. Opting for certified service not only preserves existing warranty benefits but also protects your investment, ensuring optimal appliance longevity and reliability.

Identifying Compressor Issues

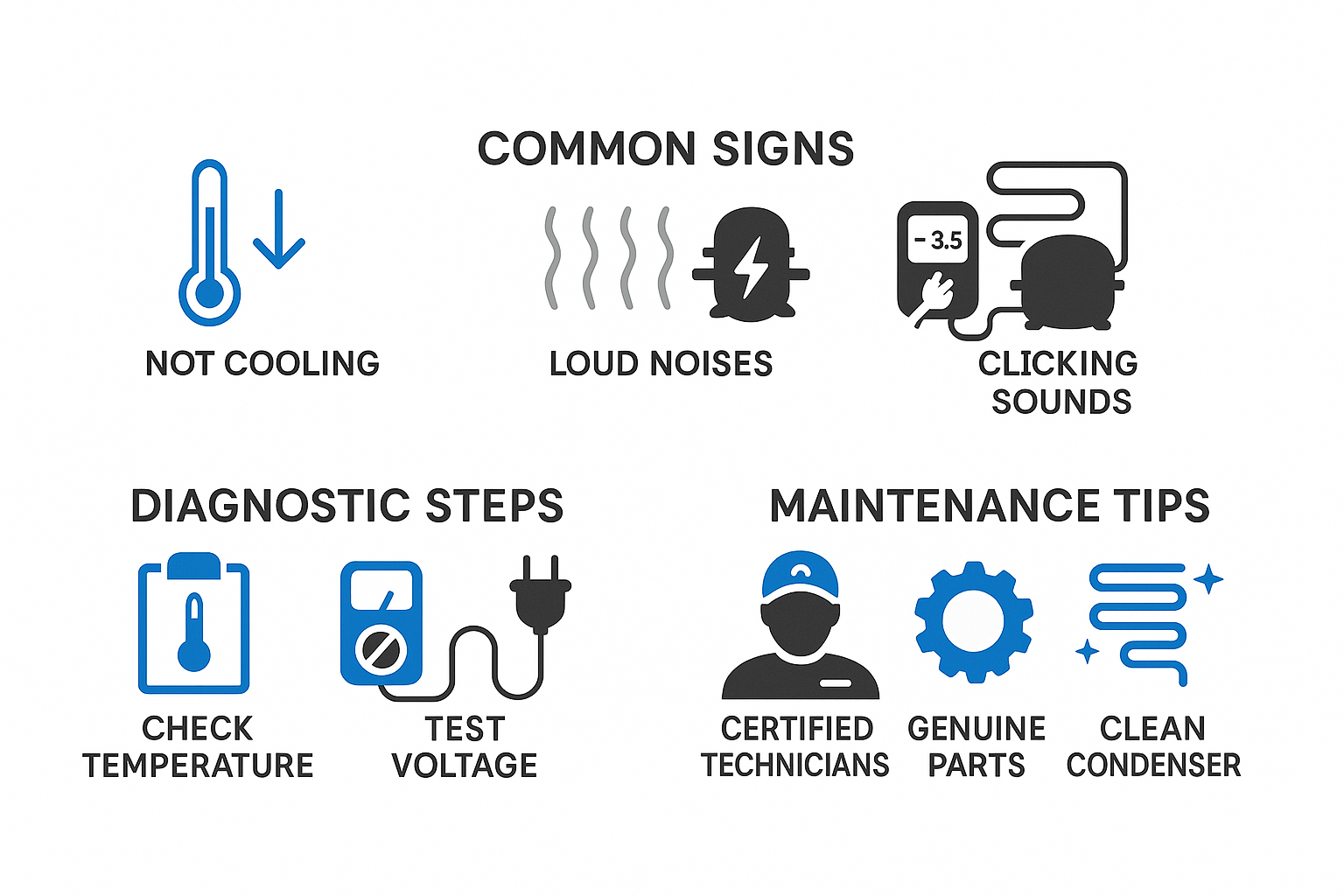

Technical infographic highlighting common compressor issues and maintenance tips for Sub Zero refrigerators, designed for clarity and professionalism.

Understanding the symptoms and diagnostics behind compressor failure can help you act quickly and minimize downtime for your Sub Zero appliance.

Common Signs of Compressor Failure

Some of the most prevalent indications of compressor trouble are readily noticeable if you know what to look for. The moment you perceive inconsistent cooling or hear persistent humming, clicking, or rattling from your refrigerator, it’s time for investigation. Additional compressor failure signs consist of:

- Persistent warm zones within the fresh food or freezer compartments, regardless of thermostat settings

- Excess moisture, frost, or ice accumulating on internal components

- The compressor running constantly or shutting off too frequently

- Unusual overheating on the unit’s back panel

- Frequent circuit breaker trips when the appliance cycles on

Though some of these symptoms can signal other issues (like fan or thermostat malfunctions), they often indicate imminent compressor problems demanding prompt attention from a professional Sub Zero repair specialist.

Diagnostic Procedures

Accurate diagnostics are essential before any major component replacement. Trained technicians follow a multi-step process to ensure precision:

- Refrigerant level checks to ensure no leaks or environmental hazards

- Electrical continuity testing on both start and run windings

- Thermostat and sensor validation to rule out simple electrical issues

- Inspection for burnt wiring, visible oil leaks, or signs of physical compressor damage

For high-end Sub Zero models, some diagnostics require specialized tools–another reason certified technicians are indispensable.

Preventative Maintenance Tips

Proper preventative maintenance substantially reduces your risk of major compressor failure. Leading recommendations include:

- Regular coil cleaning at least twice a year

- Routine inspection of door seals for airtight closure

- Monitoring for unusual frost or condensation

- Refrigeration maintenance per EPA guidelines, emphasizing leak detection and refrigerant recovery

- Scheduling annual tune-ups with certified technicians

Well-maintained Sub Zero appliances routinely last beyond 20 years, with compressors that perform reliably for over a decade when serviced regularly.

Repair Costs and Considerations

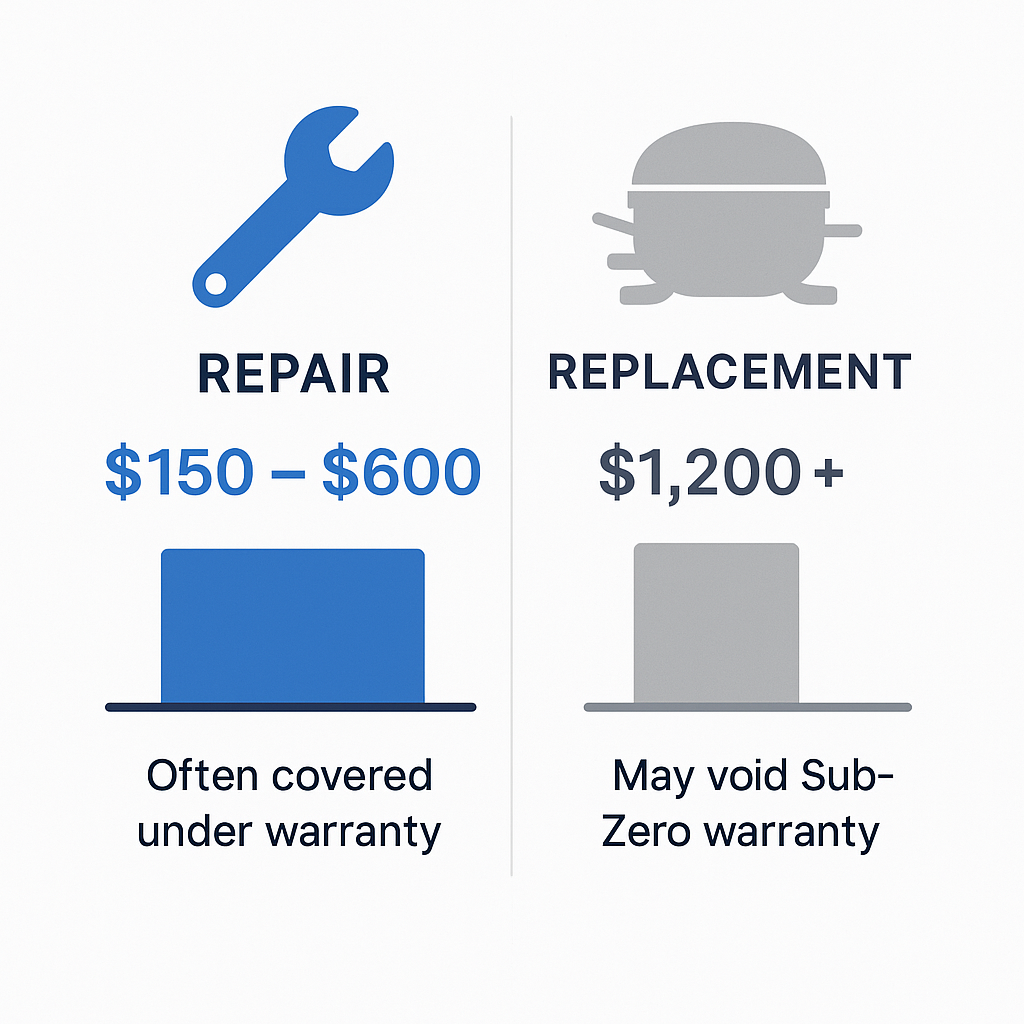

Comparison chart of repair vs replacement costs and warranty considerations for Sub Zero refrigerator compressors.

Typical Cost Breakdown

The cost to repair or replace a compressor in a Sub Zero refrigerator is influenced by parts, specialized labor, and geographic location. Here’s what you should expect:

- Compressor repair cost: $1,200-$2,500 (including parts and labor)

- Standard repair costs for non-sealed system issues: $200-$600

- Additional diagnostic fees may apply, usually ranging from $80-$150, often credited toward final repairs

Choosing authorized service providers ensures transparent pricing and the use of genuine components.

Repair vs Replacement Decisions

When are compressor replacement or a full appliance upgrade the right choice? Factors to consider:

- Age of unit: Sub Zero refrigerators beyond 15 years may be candidates for upgrade

- Repair cost vs value: If repair exceeds 50% of replacement price, a new appliance could be prudent

- Condition of other components–frequent leaks or electrical failures may favor replacement

- Appliance model, as certain classic units are worth restoring for their build quality

Careful evaluation with a certified technician will help you make the most cost-effective decision for your luxury kitchen.

Warranty and Service Plans

Compressor work can affect your appliance warranty. Opting for factory-certified repair preserves valuable warranty benefits, including:

- Manufacturer parts and labor guarantees

- Extended coverage through approved service plans

- Repair guarantees when using authorized vendors

Protecting your warranty ensures peace of mind in the event of future issues.

DIY Repair Feasibility and Safety

Attempting DIY compressor repair on a Sub Zero refrigerator is not advisable for most owners. Here’s why expert intervention is critical.

Why DIY is Not Recommended

Sub Zero compressors operate under high pressure, contain refrigerants, and require advanced tools for servicing. Attempting repairs without experience can:

- Lead to refrigerant leaks (hazardous to health and the environment)

- Result in electrical shocks, burns, or further damage

- Void existing warranties or cause regulatory violations

The complexity and risk involved mandate professional service, both for safety and regulatory compliance.

Safety Concerns and Regulations

Handling refrigerant and sealed components is governed by strict refrigerant handling certification and EPA guidelines. Only certified technicians can legally:

- Recover and recharge refrigerants

- Perform sealed system repairs

- Ensure environmentally responsible disposal and containment

Ignoring these rules isn’t just risky–it’s illegal.

When to Call Certified Technicians

When you observe:

- Sudden loss of cooling

- Loud, repetitive compressor noises

- Tripped circuit breakers or burning smells

It’s vital to reach out to certified technicians who can restore your appliance while protecting your warranty and safety.

Repair Process and Duration

Visual guide depicting the stepwise repair process for Sub Zero refrigerator compressors, from diagnosis through testing.

Step-by-Step Repair Overview

The professional repair process for a Sub Zero compressor typically unfolds as follows:

- Diagnosis and refrigeration system pressure check

- Safe recovery of old refrigerant to comply with regulations

- Disassembly and removal of faulty compressor

- Installation of a genuine Sub Zero replacement compressor

- System recharging with approved refrigerant

- Leak testing and performance verification

Precision at each stage is critical for restoring full function and ensuring efficiency.

Typical Repair Timeframes

A repair duration of 2-4 hours is standard for most Sub Zero compressor jobs, depending on:

- Appliance model

- Accessibility within cabinetry

- Complexity of the sealed system

Professional teams coordinate logistics so you receive rapid, minimally disruptive service–especially with same day Sub Zero repair options in select areas.

Importance of Genuine Parts

Using non-OEM or generic parts threatens compatibility and voids warranties. Insist on factory parts for all repairs to ensure:

- Proper fit and function

- Extended appliance life

- Full protection of all warranty benefits

Supporting Services and Related Repairs

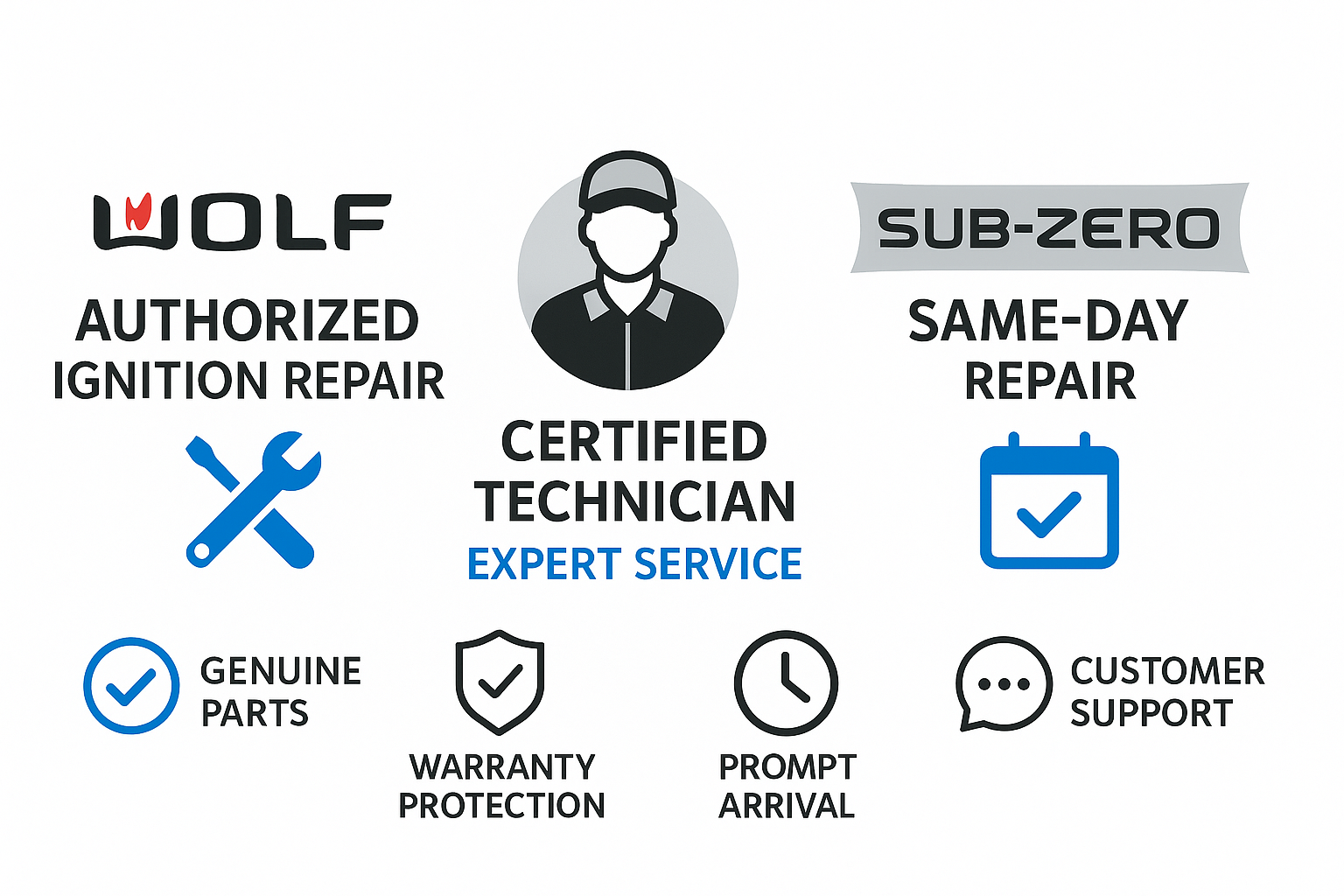

Visual infographic emphasizing supporting repair services and certified technician expertise for Wolf ignition and Sub Zero repairs.

Sub Zero Repair Professionals offer a suite of related high-end appliance services to support your luxury kitchen.

Wolf Range Ignition Repair Service

If you notice erratic sparking, ignition gaps, or a lack of flame in your Wolf range, immediate Wolf range ignition repair is crucial for safety and meal preparation. The Wolf range ignition repair service addresses:

- Faulty ignitors and broken spark wires

- Dirty or blocked ignition ports

- Malfunctioning spark modules

Certified service protects your investment and keeps your kitchen running smoothly.

Same Day Sub Zero Appliance Repair

When emergencies strike–such as a failed compressor or sudden cooling loss–same day Sub Zero appliance repair restores your appliance’s performance with:

- 24/7 availability for urgent repairs

- Transparent pricing with no hidden fees

- Rapid dispatch of expert technicians

This premium, expedited service is ideal for Pasadena residents seeking Sub Zero refrigerator repair Pasadena and nearby cities.

Certified Technician Benefits

Choosing certified technicians guarantees:

- Warranty compliance and access to factory parts

- Advanced diagnostics using state-of-the-art equipment

- Professional Sub Zero repair that maximizes appliance value

- Customer testimonials and reputation for excellence

Owners that rely on certified service professionals consistently report higher satisfaction and longer appliance lifespan, validated by actual customer testimonials.

Conclusion

Sub Zero refrigerators stand as the gold standard in luxury home refrigeration, but their advanced design also means they demand the highest level of care. Addressing compressor issues requires more than quick fixes–it calls for specialized expertise and genuine components.

By spotting trouble early, investing in Sub Zero refrigerator compressor repair from certified technicians, and prioritizing same day Sub Zero repair when necessary, you safeguard the performance, value, and warranty benefits of your most essential kitchen investment. Remember, attempting DIY compressor repair may cost far more in the long run than trusting an expert.

Contact certified Sub Zero repair professionals today to ensure fast, reliable compressor repair and protect your luxury appliance investment.

Resources

Sub-Zero Repair Costs | How to Guides

Sub-Zero Compressor Replacement

How Much Does It Cost to Replace a Sub-Zero Refrigerator Compressor?

Repair and Reclaim of Refrigeration and Air Conditioning Equipment

How Much Does a Refrigerator Compressor Cost in 2025?

Ignition Repair

Refrigeration Academy

Sub-Zero Success Stories

Sub Zero Repair Carrollton Sub Zero Service Harlingen Sub Zero Maintenance Round Rock